How to know whether you need to wax your skis?

It's a well-known fact that waxing the base of a ski is a compulsory operation before setting off into the mountains, and is part of the regular maintenance you need to carry out on your ski equipment. It must be renewed frequently if you ski often. Racers wax before every training session or competition, but recreational skiers ideally wax at the beginning and end of the season to 'nourish' the base during the period when the skis are stored (summer ski servicing). If you notice that the gliding properties of the skis have deteriorated or if the base is damaged, you can re-wax them during the season. But before going on to the actual waxing, it's important to understand what a ski base is.

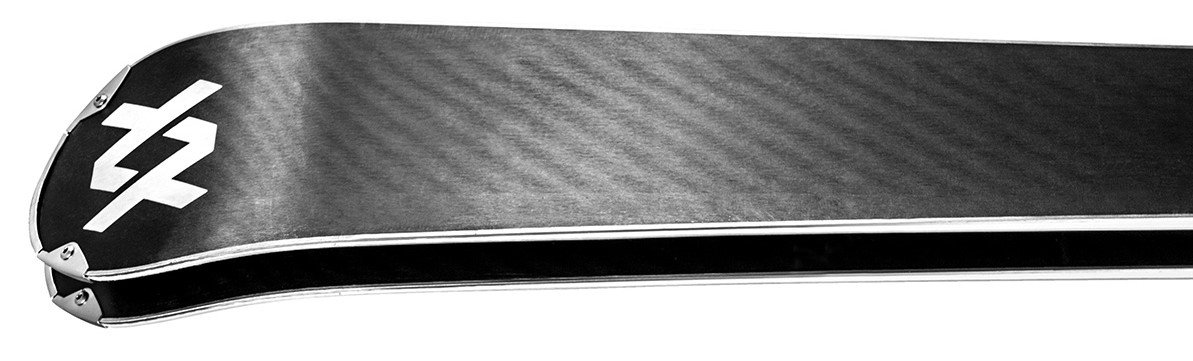

Understanding the ski base structure

Each base has a structure designed to improve glide. Small oblique grooves help evacuate the water that accumulates under the tip of the skis when skiing. Waxing improves the properties of the base while protecting it from oxidation. This process considerably increases the ski's gliding ability.

Paraffin, wax, waxing iron… What are the supplies and equipment required for ski maintenance?

- 1 block of cleaning paraffin,

- 1 block of universal ski wax,

- 1 waxing iron,

- 1 plastic scraper,

- 1 bronze brush,

- 1 soft brush.

How to prepare your skis before waxing?

Waxing your skis:

All the gear for ski maintenance at Glisshop

Glisshop has all the ski maintenance equipment you need, including wax in different colours depending on the temperature, waxing irons, brushes, as well as tools for edge tuning and minor repairs. Thanks to these accessories, your ski equipment will stay in perfect condition and give you maximum fun. You'll find everything you need for maintenance and preparation, so that your skis perform just as well on wet snow encountered during a spring ski outing, as on light powder or on groomed and abrasive snow.