The Vibram outsole is not just a material or shape; it's a key element in choosing a shoe or boot, especially when it comes to hiking and trail running models. Made of a special rubber, it offers very high resistance to abrasion as well as excellent grip on all types of terrain.

In short

- The Vibram sole provides outstanding grip and durability on all types of terrain.

- Developed in 1935 following a mountaineering accident to enhance traction.

- Vibram rubber is engineered for optimal grip and long-lasting performance.

- The Carrarmato tread pattern ensures excellent traction on rock and snow.

- Each sole type is designed for a specific activity (hiking, trail running, climbing, etc.).

- Megagrip delivers superior adhesion on dry, wet, or icy surfaces.

- Litebase reduces weight for a more responsive stride in trail running.

- Ecostep incorporates recycled materials for a lower environmental impact.

- In hiking and trail running, Vibram ensures stability and long-lasting wear.

- Regular maintenance includes proper cleaning, gentle drying, and inspection for wear.

History and Development of the Vibram Sole

Its history dates back to 1935, when Vitale Bramani decided to create a durable vulcanized rubber outsole. Today, it has become a benchmark in the world of footwear, found on models for walking, hiking, trail running, climbing, and mountaineering.

The birth of Vibram soles is closely linked to an alpine tragedy. In 1935, Vitale Bramani, an Italian alpinist, lost six of his companions during an ascent. The insufficient grip of their studded leather boots was identified as the main cause of the accident. Driven by this painful experience, Bramani embarked on the development of an outsole that offered better traction. He then created the Carrarmato sole, thanks to vulcanized rubber technology, which revolutionised the world of mountaineering.

Since this invention, the Vibram brand has continued to evolve, becoming the market leader in quality rubber soles. They are now used in many fields, ranging from outdoor activities to orthopaedics.

Composition and Specifics of Vibram Rubber

The rubber used in Vibram soles is specifically designed to offer optimal grip on all types of terrain. It is a synthetic blend that uses a combination of different ingredients depending on the type of sole, directly influencing the performance of the final product.

Initially, Vibram soles were made of vulcanized natural rubber. However, the company has gradually moved to synthetic blends to improve the characteristics of its soles.

Some Vibram soles are characterised by the presence of a shock-absorbing midsole made of a soft compound. This guarantees a high level of shock absorption at the heel, thereby increasing comfort.

In addition to the materials used, the design of Vibram soles also plays a key role. For example, the Montagna Vibram version with its famous ‘Carrarmato’ pattern ensures excellent grip on rock and snow.

The Different Types of Vibram Soles

The diversity of Vibram outsoles is impressive, with a large number of variations available, each model designed for a specific application. Among which we can mention:

Vibram Carrarmato

Launched as Vibram's first major innovation, the Carrarmato sole has become a benchmark in the world of alpinism. Its unique rubber design, featuring deep grooves inspired by tank tracks, offers unparalleled traction on difficult terrains. Its durability and ability to grip to various surfaces make it a preferred choice for alpinists and adventurers seeking reliable performance.

Vibram Megagrip

The Vibram Megagrip sole is designed to provide superior grip in various conditions, whether on wet, dry, or icy surfaces. This versatility makes it an ideal choice for outdoor enthusiasts who encounter a range of terrains. Its special formulation allows for exceptional traction while maintaining good durability.

Vibram Litebase

Specially designed for running and trail running shoes, the Vibram Litebase sole combines lightness and performance. It is engineered to provide excellent grip and remarkable durability without weighing down the shoe, thus allowing runners to enjoy a natural and responsive running experience. The significant reduction in rubber thickness helps to improve the weight of the shoes, without compromising on the sole's traction, grip, or durability.

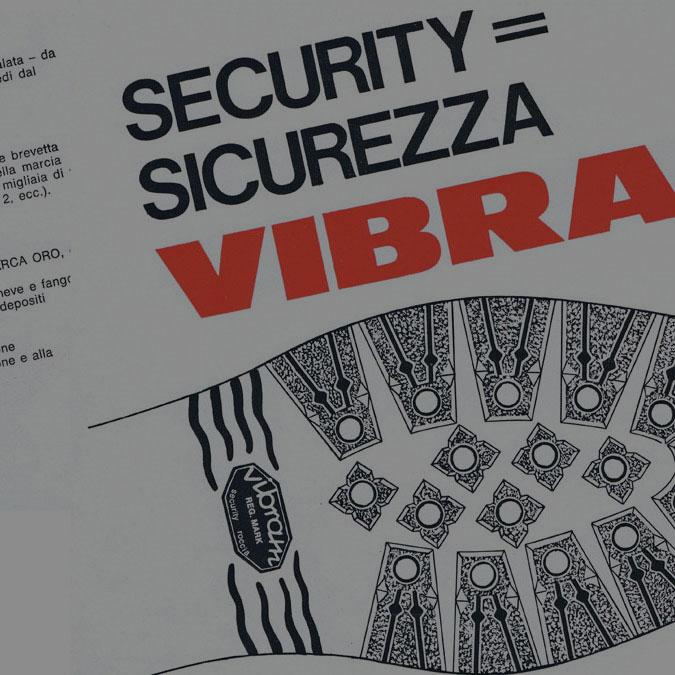

Vibram Security

Specifically aimed at the security market, the Vibram Security sole is made of an oil-resistant rubber blend, ensuring increased longevity and strength. It is designed to meet the rigorous requirements of professionals in terms of safety and durability.

Vibram Ecostep

In its ongoing effort to reduce its environmental footprint, Vibram has created the Vibram Ecostep sole, an eco-friendly innovation that incorporates production waste. This approach significantly reduces waste and the need for new materials by up to 30%. A pioneer in the use of eco-friendly materials, Vibram continues to lead the way in sustainable development.

Vibram XS Grip

Revolutionary in the field of free climbing shoes, the Vibram XS Grip sole uses a tacky rubber specially designed for this sport. It offers exceptional grip on rock, enhancing climbers' performance and safety.

Vibram Soles for Hiking and Trail Running

Vibram soles stand out for hiking and trail running thanks to their versatility and durability. They adapt to various types of terrain you may encounter, whether rocky, muddy, slippery, or snowy.

For hiking, shoes and boots with Vibram soles offer optimal grip, even on the steepest terrains. They guarantee remarkable stability, thereby reducing the risk of slips and falls. In addition, their robustness guarantees your hiking boots will last.

For trail running, Vibram soles are also a wise choice. They provide effective traction, essential for rugged terrains. Additionally, some models incorporate Vibram Litebase technology. This technology reduces the weight of the sole without compromising its strength, thus offering improved running comfort.

Finally, Vibram outsoles can be customised according to your specific needs, whether in terms of weight, volume, flexibility, or stability on wet, dry, or icy ground.

How to Care for your Vibram Soles?

To maintain the optimal performance of your Vibram soles and extend their lifespan, regular maintenance is essential. Here are some tips for taking care of your Vibram soles:

- Routine cleaning: After every use, clean your soles with warm water and a soft brush to remove mud, rocks, and debris. Avoid using harsh detergents that could damage the rubber.

- Drying: Let your shoes dry naturally in a well-ventilated area. Avoid direct heat sources like radiators or shoe dryers, as excessive heat can deform or damage the rubber.

- Routine inspection: Regularly check your soles for any signs of excessive wear, cuts, or detachment. Uneven wear might indicate a gait issue that requires attention from a specialist.

- Repair: For minor damages or detachment, you can perform minor repairs using appropriate glues for shoe soles. For more significant repairs, visit a professional cobbler.

How to Effectively Glue a Vibram Sole?

To effectively glue a Vibram sole, start by thoroughly cleaning the surface of your new sole with hot water to remove any dirt or dust. Ensure that the sole is completely dry before beginning the gluing process.

Next, apply a thin layer of specific adhesive for soles (check with a with a cobbler or specialised store) to both surfaces to be joined. Apply carefully and uniformly to ensure good bonding.

Allow the adhesive to dry until it becomes matte, indicating it is ready for use.

Finally, press the two parts firmly together, taking care to align the edges correctly. Use a heavy object to maintain pressure while the adhesive dries completely.

It is recommended to leave the shoe in a dry place for at least 24 hours before using it again.